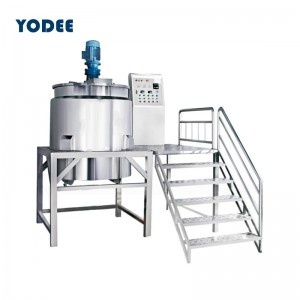

Heated stainless steel liquid mixing tanks with agitator

Feature

● All-round wall scraping and mixing, using frequency conversion speed control, can produce high-quality products with different processes according to customer requirements.

● Diversified high-speed homogenizer, strong mixing of solid and liquid raw materials can quickly dissolve insoluble materials such as AES/AESA/LSA in liquid washing production, saving energy consumption and greatly shortening the production cycle.

● The pot body is welded with three layers of stainless steel, and the tank body and pipes are mirror polished, which meets the requirements of GMP.

● According to the process requirements, the tank body can heat and cool the material.

Structure type

Three-layer stainless steel tank, the upper part is opened, the upper part is scraped and stirred (one-way/two-way), the lower part has a head structure, the bottom inner/outer circulation homogenizer, the jacket can be heated (electricity/steam), cooled, and external insulation layer.

The tank body and the tank cover can be connected by flange sealing or welding. The stirring tank body and stirring tank cover can open process pipe holes such as feeding, discharging, observation, temperature measurement, pressure measurement, steam fractionation, and safe venting according to the process requirements.

The upper part of the stainless steel mixing tank cover is equipped with a transmission device (motor or reducer), and the agitator in the mixing tank is driven by the transmission shaft.

The shaft sealing device can adopt various forms such as mechanical seal or packing, labyrinth seal (determined according to user needs).

The agitator can be configured in various forms such as paddle type, anchor type, frame type, and spiral type.

Parameter

| Model | Working volume | Homogenizer motor(kw/rpm) | Mixing motor(kw/rpm) | Machine dimension | ||

| YDM-100 | 100L | 2.2 | 0-3300 | 1.5 | 0-63 | 1500*1200*2500mm |

| YDM-300 | 300L | 3 | 0-3300 | 2.2 | 0-63 | 2100*1800*2900mm |

| YDM-500 | 500L | 5.5 | 0-3300 | 3 | 0-63 | 2400*2100*3000mm |

| YDM-1000 | 1000L | 7.5 | 0-3300 | 4 | 0-63 | 2600*2400*3300mm |

| YDM-2000 | 2000L | 15 | 0-3300 | 5.5 | 0-63 | 3000*2800*4000mm |

| YDM-3000 | 3000L | 18.5 | 0-3300 | 7.5 | 0-63 | 3200*3000*4200mm |

| YDM-4000 | 4000L | 22 | 0-3300 | 7.5 | 0-63 | 3400*3000*4500mm |

| YDM-5000 | 5000L | 37 | 0-3300 | 11 | 0-63 | 3500*3200*4800mm |

| YDM-10000 | 10000L | 55 | 0-3300 | 22 | 0-63 | 4800*4200*5500mm |

Maintenance

Customized according to customer product particularity and actual needs.