The food industry is under increasing pressure to meet the demands of an increasingly urbanizing world population. YODEE has a broad product portfolio covering the entire food production equipment. From standard factory systems to custom solutions, all YODEE food technologies are designed to meet the best hygiene and quality standards while operating efficiently and sustainably to help our customers achieve flexible and cost-effective food production.

For example, thickeners such as gums and starches are used in low-fat products to replace the viscosity and swelling effect of oils, enhance mouthfeel, and ensure a stable emulsion.

Large-scale production is usually carried out using specially designed factories, the process is semi-automated and production is carried out under vacuum. For the typical R&D, pilot and small-scale production of the "ready-to-use" market - the way mayonnaise is produced requires greater flexibility, especially when changing recipes.

Some typical recipes are as follows:

|

80% Oil Formula |

Low Fat Formula |

||

|

Vegetable oil |

80% |

Vegetable oil |

50% |

|

Egg yolk |

6% |

Egg yolk |

4% |

|

Other thickeners |

4% |

||

|

Vinegar |

4% |

Vinegar |

3% |

|

Sugar |

1% |

Sugar |

1.5% |

|

Salt |

1% |

Salt |

0.7% |

|

Spices (e.g. mustard) |

0.5% |

Spices |

1.5% |

|

Water |

7.5% |

Water |

35.3% |

In the first stage of production, eggs, which can be used in liquid or powder form, are dispersed into water. This acts as an emulsifier.

The remaining continuous phase ingredients are then added and mixed until dispersed and hydrated.

The oil is added as fast as the continuous phase absorbs the oil. This leads to a sharp rise in product viscosity as the emulsion forms

Question:

Continuous phase ingredients make up only a small part of the overall formulation, but they play a vital role. The mixing equipment must be able to properly disperse and hydrate these substances in relatively low liquid volumes. If eggs and other emulsifiers are not properly dispersed and hydrated, the emulsion may break during the oil addition stage.

Hydration of stabilizers and thickeners is one of the most difficult mixing operations. The solution may have to be stirred for extended periods of time to complete the hydration. It is easy to form clumps; these cannot be resolved by agitation alone.

Due to the high proportion of oil in the formula, the emulsion may break if the oil is not added to the continuous phase properly. This is difficult to control when adding oil manually.

The oil phase droplets must be reduced to the smallest size possible to maximize the surface area of the oil in the continuous phase to ensure a stable emulsion. This is not easy to achieve without specialized equipment.

Aeration must be minimized or eliminated to maximize product shelf life.

Production process:

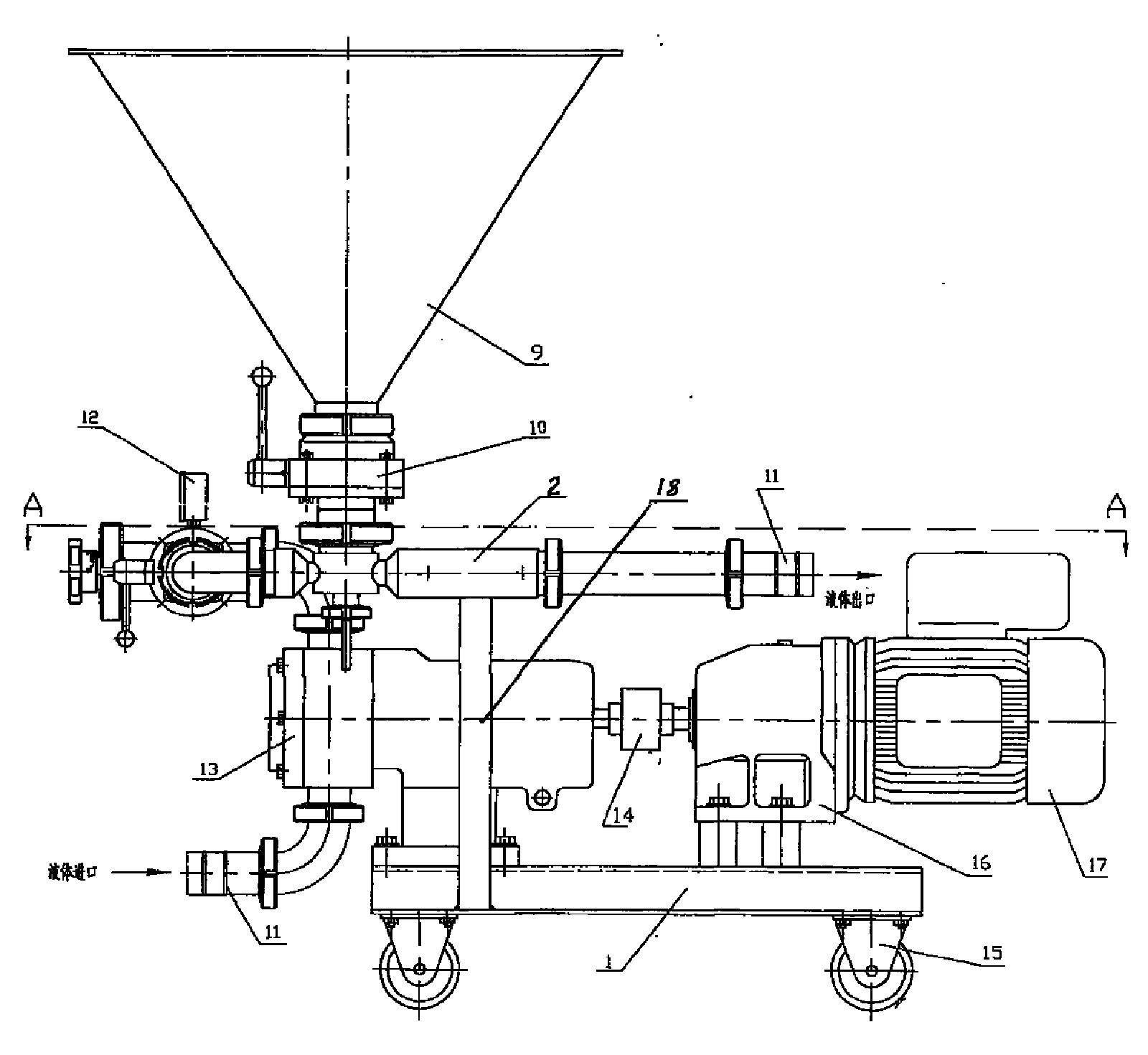

1. Water is recirculated from the vessel through the system through a specially designed in-line mixer. Eggs (powder or liquid) are added to a container and quickly wetted and dispersed into a high velocity liquid stream.

2. Then add the remaining water phase ingredients to the container. Recirculation continues until the ingredients are fully dispersed and hydrated.

3. The oil inlet valve opens and oil is pumped from the hopper into the water phase at a controlled rate. The water and oil phase components enter directly into the working head of the inline mixer, where they are subjected to intense high shear. This finely disperses the oil into the water phase, forming an emulsion immediately. Vinegar (and/or lemon juice) is added with the final oil.

4. Recirculation of the product continues to ensure a uniform consistency as the viscosity increases. After a short recirculation period, the process is complete and the finished product is discharged.

Advantage:

Great for small batches for immediate use.

Minimize aeration.

The system virtually eliminates operator error.

Provides batch-to-batch consistency and stability of turnkey factory-produced mayonnaise without high capital expenditures.

Since the thickener is fully hydrated and the other ingredients are properly dispersed, the yield of the raw material is maximized.

The system is designed to handle high viscosity products without the need for additional pumps or auxiliary equipment.

Easily adapt to changes in product type and formulation.

YODEE also supports the design, manufacture, transportation, installation and subsequent equipment maintenance of large-scale industrialized full-automatic production lines. The products in the food category are typically mayonnaise, salad dressing, mustard, honey and other products. The requirements of the process make us The material requirements of the machine are more stringent, and food grade SUS304 stainless steel and food grade SUS316L should be used as the main material of the machine. Homogenization, emulsification, stirring, and packaging in food equipment are particularly important.

For detailed prouct supporting equipment and technical data, please contact YODEE related business personnel.