PriceList for Vacuum Emulsifier Homogenizer - Vacuum emulsifying mayonnaise homogenizer mixer making machine – YODEE

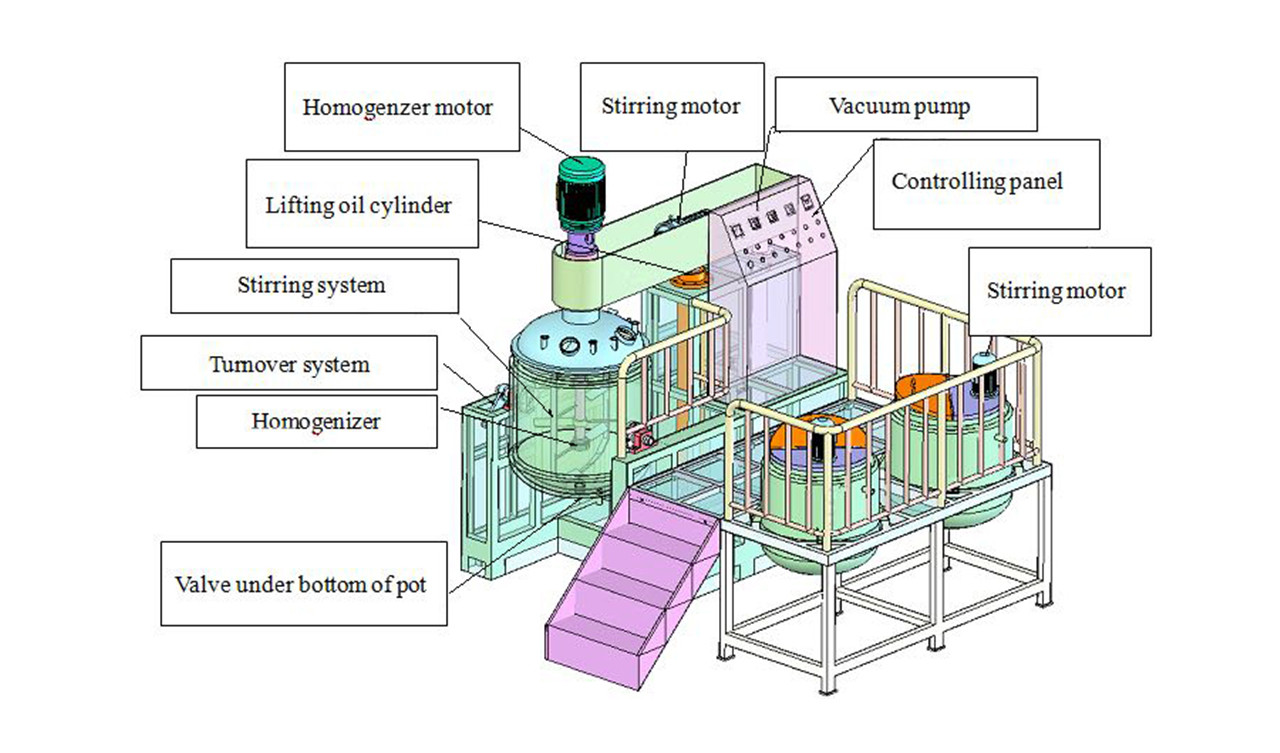

PriceList for Vacuum Emulsifier Homogenizer - Vacuum emulsifying mayonnaise homogenizer mixer making machine – YODEE Detail:

It is cut in the shearing slit and quickly broken into particles of 200nm-2um. Since the emulsification tank is in a vacuum state, the bubbles generated during the stirring process of the material are removed in time. Vacuuming is used to prevent the products from being mixed with air bubbles during the stirring process, so as to ensure that high-quality products with luster, fineness and good ductility can be produced.

Function

● Heating: Steam heating or electric heating.Electric heating is suitable for small-capacity machines, and steam heating is suitable for large-capacity machines. Compared with electric heating, steam heating can heat faster per unit time. It is convenient to add more equipment later to design an automatic control system.

● Stirring: Low-speed stirring 0-63r/min can quickly and evenly mix various raw materials.

● Homogenization: The high shear speed of 0-3300r/min can more efficiently dissolve oil and water to form high-quality products.

● Material suction: In the state of vacuum, liquid raw materials and powder raw materials can be quickly transferred to the container for production through the vacuum suction pipe.

● Vacuum: Make the container form a vacuum sterile environment, adding powder in the vacuum environment can avoid dust pollution and prevent material agglomeration.

Parameter

| Capacity | Homogenizer Motor(KW) | Stirring motor(KW) | Vacuum pump(KW) | water pot stirring(KW) | oil pot stirring(KW) | water pot heating(KW) | oil pot heating(KW) |

| 250L | 5.5 | 2.2 | 1.5 | 0.55 | 0.55 | 12 | 9 |

| 300L | 5.5 | 3 | 3 | 0.75 | 0.75 | 18 | 9 |

| 400L | 7.5 | 4 | 3 | 0.75 | 0.75 | 18 | 9 |

| 500L | 11 | 4 | 3 | 1.1 | 1.1 | 18 | 9 |

| 1000L | 15 | 5.5 | 3.85 | 1.5 | 1.5 | 27 | 18 |

| 2000L | 18.5 | 7.5 | 3.85 | 2.2 | 2.2 | 36 | 27 |

| 3000L | 22 | 11 | 11 | 3 | 3 | ||

| 5000L | 37.5 | 15 | 11 | 5.5 | 5.5 |

Optional System

● Button control/PLC color touch screen

● Cleaning spray ball/CIP system/SIP system

● Piping system (steam pipe / pure water pipe / tap water pipe / cooling water pipe / sewage pipe / air pipe)

● Remote control system

Product detail pictures:

Related Product Guide:

It is a good way to improve our products and service. Our mission is to develop creative products to customers with a good experience for PriceList for Vacuum Emulsifier Homogenizer - Vacuum emulsifying mayonnaise homogenizer mixer making machine – YODEE , The product will supply to all over the world, such as: Roman, Senegal, Mexico, What is good price? We provide customers with factory price. In the premise of good quality, efficiency will have to be paid attention to and maintain appropriate low and healthy profits. What is a fast delivery? We make the delivery according to customers' requirements. Although delivery time depends on the order quantity and the complexity of it, we still try to supply products and solutions in time. Sincerely hope we could have long term business relationship.

Sales manager is very enthusiastic and professional, gave us a great concessions and product quality is very good,thank you very much!