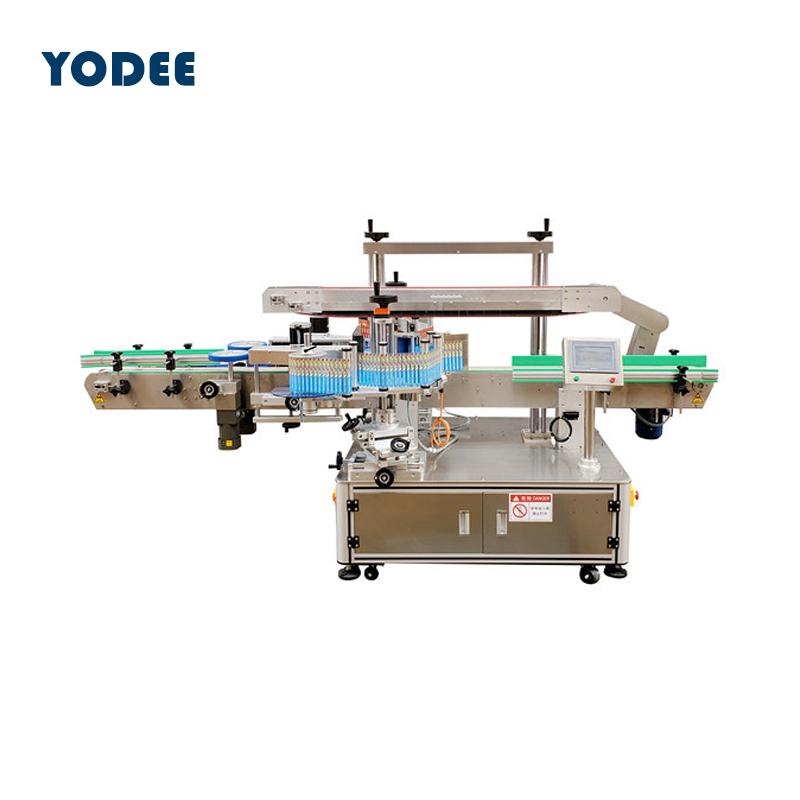

Factory Supply Water Bottle Labeling Machine – Automatic position double side labeling machine for flat round bottle – YODEE

Factory Supply Water Bottle Labeling Machine – Automatic position double side labeling machine for flat round bottle – YODEE Detail:

YODEE has always been in the front line of service in the machinery industry, and the problems faced by customers are the direction of our research and design. The high speed single-head automatic filling machine was redesigned according to some needs of customer feedback

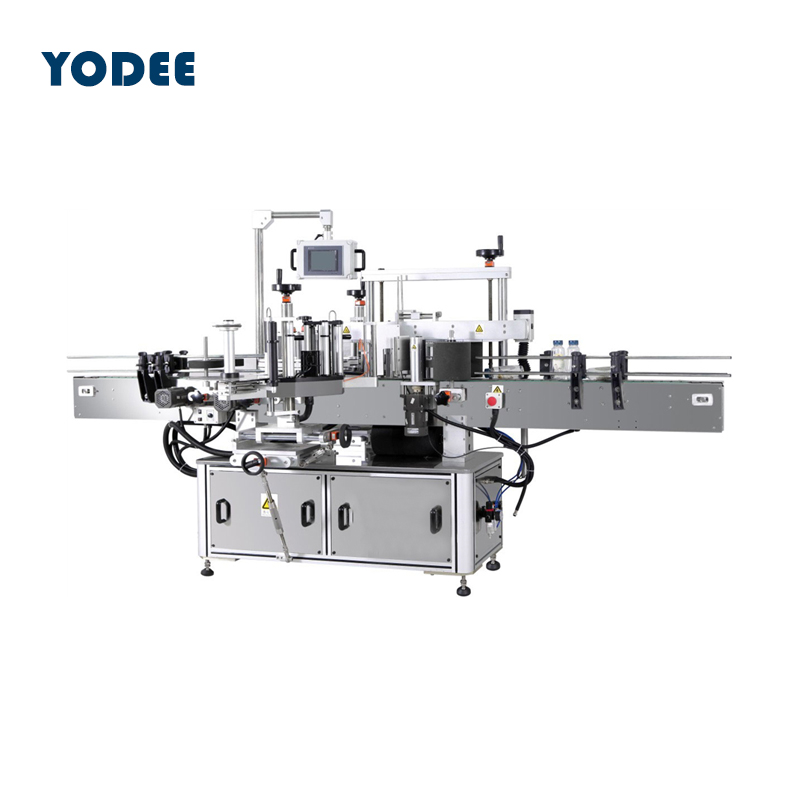

Working Principle

After the sensor detects that the product has passed, it sends back a signal to the labeling control system, and the control system controls the label at the appropriate position to send out the label and attach it to the position where the product is to be labelled. The product flows through the label covering device, the label is covered and attached to the product, and the attachment action of a label is completed.

Filling Speed

Put the product (can be connected to the assembly line) → product conveying → product separation → automatic labeling → collect the labelled products.

Features

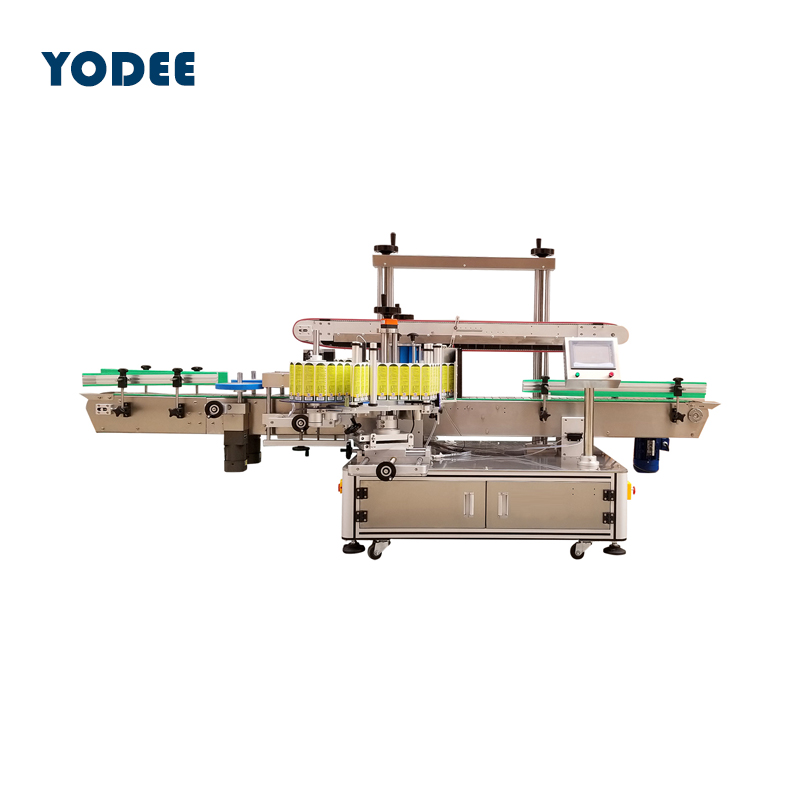

● Powerful function, one machine can realize single-sided and double-sided labeling of 4 products (round bottle, flat bottle, square bottle, special-shaped bottle).

● The double-sided rigid plastic synchronous guide chain is used to automatically ensure the neutrality of the bottle and reduce the requirements for workers to put bottles and line into bottles.

● It can be produced by a single machine or connected to an assembly line; it is equipped with a spring-pressing top-pressing mechanism to ensure smooth product delivery and effectively eliminate the error of the bottle height itself.

● Equipped with an automatic bottle separation mechanism, which automatically separates the distance before guiding the bottle to ensure the stability of subsequent bottle guiding, transportation and labeling.

● Intelligent control, automatic photoelectric tracking. It has the functions of no label, no label automatic correction and label automatic detection function, to avoid wasting labels and missing labels.

Parameter

| Label Accuracy | ±1mm (Does not include product, label errors) |

| Label Speed | 60~150 bot/min(depends on label size) |

| Bottle Diameter) | Length: 20-250mm Width: 30-90mm Height: 60-280mm |

| Label size | Length: 20-300mm Width: 20mm~170mm |

| Application power | 220V/50HZ |

| Machine size | 3020×1560×1600mm |

| Machine weight | 180Kg |

Product detail pictures:

Related Product Guide:

We know that we only thrive if we can guarantee our combined price tag competiveness and top quality advantageous at the same time for Factory Supply Water Bottle Labeling Machine – Automatic position double side labeling machine for flat round bottle – YODEE , The product will supply to all over the world, such as: Seattle, Ghana, Estonia, Our products have been obtained more and more recognition from foreign clients, and established long term and cooperative relationship with them. We`ll provide the best service for every customer and sincerely welcome friends to work with us and establish the mutual benefit together.

Production management mechanism is completed, quality is guaranteed, high credibility and service let the cooperation is easy, perfect!