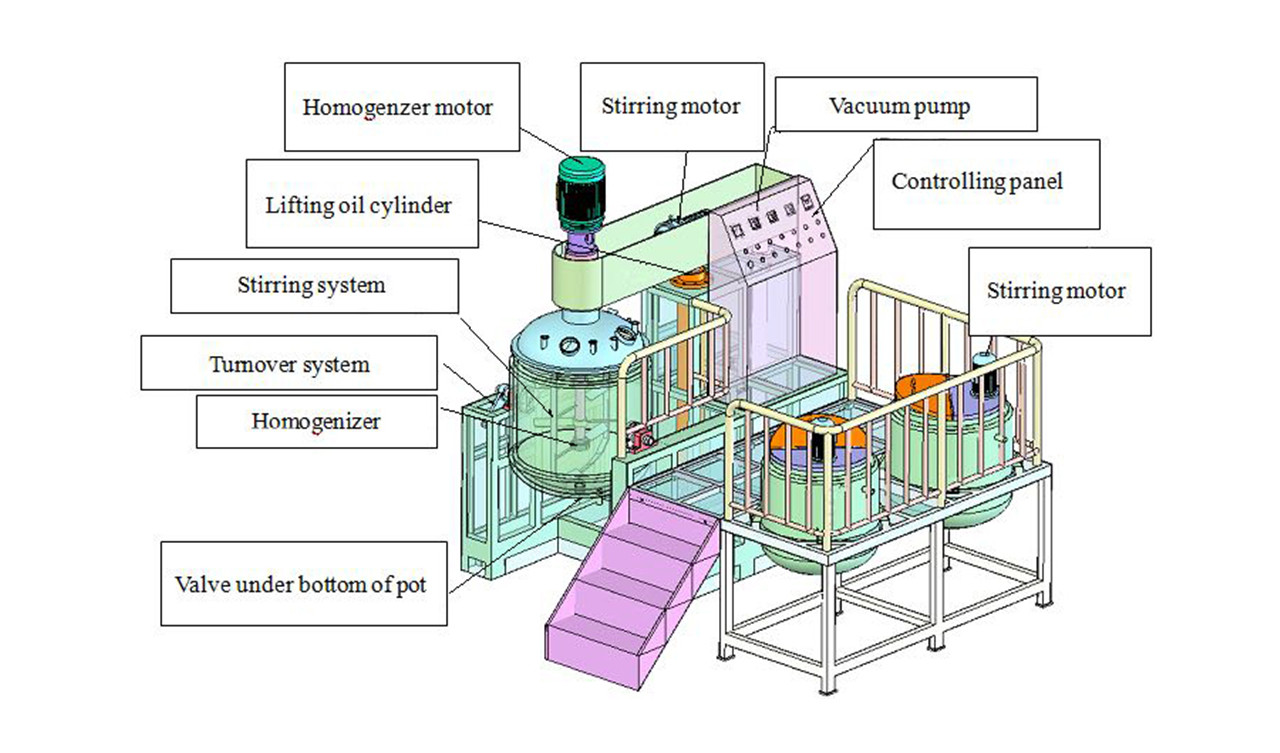

Best quality Cosmetic Cream Mixer Machine - Vacuum emulsifying mayonnaise homogenizer mixer making machine – YODEE

Best quality Cosmetic Cream Mixer Machine - Vacuum emulsifying mayonnaise homogenizer mixer making machine – YODEE Detail:

It is cut in the shearing slit and quickly broken into particles of 200nm-2um. Since the emulsification tank is in a vacuum state, the bubbles generated during the stirring process of the material are removed in time. Vacuuming is used to prevent the products from being mixed with air bubbles during the stirring process, so as to ensure that high-quality products with luster, fineness and good ductility can be produced.

Function

● Heating: Steam heating or electric heating.Electric heating is suitable for small-capacity machines, and steam heating is suitable for large-capacity machines. Compared with electric heating, steam heating can heat faster per unit time. It is convenient to add more equipment later to design an automatic control system.

● Stirring: Low-speed stirring 0-63r/min can quickly and evenly mix various raw materials.

● Homogenization: The high shear speed of 0-3300r/min can more efficiently dissolve oil and water to form high-quality products.

● Material suction: In the state of vacuum, liquid raw materials and powder raw materials can be quickly transferred to the container for production through the vacuum suction pipe.

● Vacuum: Make the container form a vacuum sterile environment, adding powder in the vacuum environment can avoid dust pollution and prevent material agglomeration.

Parameter

| Capacity | Homogenizer Motor(KW) | Stirring motor(KW) | Vacuum pump(KW) | water pot stirring(KW) | oil pot stirring(KW) | water pot heating(KW) | oil pot heating(KW) |

| 250L | 5.5 | 2.2 | 1.5 | 0.55 | 0.55 | 12 | 9 |

| 300L | 5.5 | 3 | 3 | 0.75 | 0.75 | 18 | 9 |

| 400L | 7.5 | 4 | 3 | 0.75 | 0.75 | 18 | 9 |

| 500L | 11 | 4 | 3 | 1.1 | 1.1 | 18 | 9 |

| 1000L | 15 | 5.5 | 3.85 | 1.5 | 1.5 | 27 | 18 |

| 2000L | 18.5 | 7.5 | 3.85 | 2.2 | 2.2 | 36 | 27 |

| 3000L | 22 | 11 | 11 | 3 | 3 | ||

| 5000L | 37.5 | 15 | 11 | 5.5 | 5.5 |

Optional System

● Button control/PLC color touch screen

● Cleaning spray ball/CIP system/SIP system

● Piping system (steam pipe / pure water pipe / tap water pipe / cooling water pipe / sewage pipe / air pipe)

● Remote control system

Product detail pictures:

Related Product Guide:

We thinks what customers think, the urgency of urgency to act during the interests of a purchaser position of theory, allowing for much better good quality, lower processing costs, prices are extra reasonable, won the new and old buyers the support and affirmation for Best quality Cosmetic Cream Mixer Machine - Vacuum emulsifying mayonnaise homogenizer mixer making machine – YODEE , The product will supply to all over the world, such as: Vancouver, British, Afghanistan, Whether selecting a current product from our catalog or seeking engineering assistance for your application, you can talk to our customer service center about your sourcing requirements. We can provided good quality with competitive price for you personally.

Managers are visionary, they have the idea of "mutual benefits, continuous improvement and innovation", we have a pleasant conversation and Cooperation.